Industrial Valve

Industrial valves are built to handle high pressure, either from fluid or gas, and to last through years of use in harsh environments. Most utilities, every branch of the manufacturing industry and they are heavily utilised within the oil and gas industry, chemical plants and water drainage systems.

NIMEX offer bellow type Valves that vary in size and can withhold a range of pressures regulating the flow of semi-solids, liquids and gases, catering to each and every industry.

|

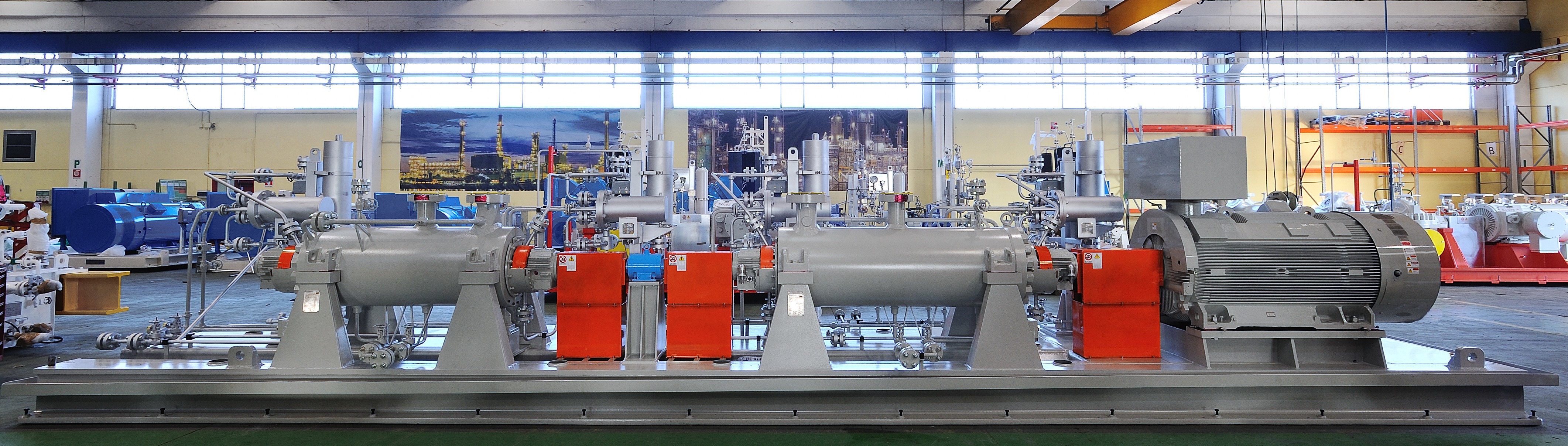

ACTUALTED CONTROL VALVE

A control valve is a device capable of modulating flow at varying degrees between minimal flow and full capacity in response to a signal from an external control device. An actuated control valve is used for particular uses such as regulating corrosive liquids in chemical plants or specific applications in electrical power and transmission grids.

NIMEX cooperate with Manufacturer in the design, development and sales of valves with all kinds of integrated control systems.

|

|

BALL VALVE

A ball valve is comprised of a valve housing, which is often a metal casting, and a perforated ball. Actuating the valve turns the ball, increasing the flow as the perforation comes in line with the channel. New developments in ball valves, such as segmented ball valves, allow greater control over flow rates.

Our technical expertise are reflected in providing perfect solutions for projects of different scale and different unites for Ball Valve application.

|

|

BUTTERFLY VALVE

A butterfly valve consists of a channel and a paddle affixed to the channel through its central axis. The paddle, which is often disc-shaped, can spin to obstruct or open the channel. Butterfly valves are another type of isolation valve; while they offer little control in terms of flow rate, they do allow large volumes of material to flow through the channel.

NIMEX ensure that our analysize, selection, calculation to select right butterfly valve products according to the initial working conditions and technical requirements. We can provide the best solution and timely delivery to meet your needs.

|

|

GATE VALVE

A gate valve consists of a channel that can be opened or closed by moving a metal gate up and down. When raised, the gate clears the channel and allows flow; when lowered, the gate obstructs the channel. Most often considered isolation, or on/off valves, gate valves have been around for decades.

|

|

GLOBAL VALVE

A Globe valves is a linear motion valve and are primarily designed to stop, start and regulate flow. The disk of a Globe valve can be totally removed from the flowpath or it can completely close the flowpath. Conventional Globe valves may be used for isolation and throttling services.

Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to avert premature failure and to assure satisfactory service. Valves subjected to high-differential pressure-throttling service require specially designed valve trim.

|

|

PLUG VALVE

A plug valve is a quarter-turn manual valve that uses a cylindrical or tapered plug to permit or prevent straight through flow through the body. The plug has a straight through full port opening. Plug valve can be used in on-off, basic moderate throttling, and diverting services. The face-to-face standard for plug valves is normally associated with ANSI Standard B16.10

NIMEX supplier of Plug Valve following Customer specific requirement.

|

|

CHECK VALVE

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps etc.

Check valves are used in many different applications such as liquids, gases, steam, condensate and other semi-liquids such as slurries.

NIMEX strive to provide with high-quality, specialty check valves as quickly and efficiently as possible

|

|

NEEDLE VALVE

Needle valves, sometimes referred to as plunger valves, are regulating valves and enable engineers to finely control and regulate water flow and pressure. Needle valves can be used in many different applications with a need for flow or pressure regulation. In water treatment and distribution, dams, reservoirs, power plants and industry needle valves are e.g.

|

|

SOLENOID

Solenoid valves are used wherever fluid flow has to be controlled automatically. They are being used to an increasing degree in the most varied types of plants and equipment. The variety of different designs which are available enables a valve to be selected to specifically suit the application.

Solenoid valves are control units which, when electrically energized or de-energized, either shut off or allow fluid flow. The actuator takes the form of an electromagnet.

|

|

PNEUMATIC

Pneumatic valve is a device that is used to control or modulate the flow of air (or another inert gas) in a pneumatic system. They do so by controlling the air or gas at the source, regulating its passage as needed into tubing, pipes, or devices in an automated pneumatic system.

There are three different uses for pneumatic valves which are regulating the pressure, controlling the flow and the directional control.

|

|

PINCH VALVE

A Pinch Valve is an economical piece of equipment that works like a tap. It has an on/off function, to shut off, allow or control the flow of any media passing through it. It is simply an industrial version of the pinch cock used in the laboratory to control the flow of fluids through rubber tubing. Pinch valves are suitable for on-off and throttling services.

|

|

ELECTRIC ACTUATORS

Electric actuators can replace the hydraulic systems by self-automated actuators which run on electrical power, eliminating the need for hydraulic pumps and tubing, delivering precision and repeatability. As they are programmable, the electric actuators are able to adapt to any situation, and hence are useful for many applications such as aircrafts.

|